Carbon fiber tubes are transforming industries due to their strength-to-weight ratio, corrosion resistance, and durability. At Carbonoid, we specialize in tapered carbon tube manufacturing, delivering innovative, lightweight solutions for applications in aerospace, sports, robotics, and more.

What Are Carbon Fiber Tubes?

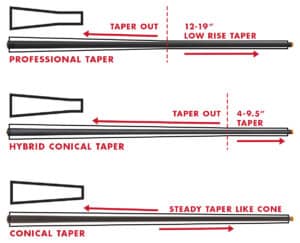

Carbon fiber tubes are cylindrical components made from carbon fiber-reinforced polymer (CFRP), recognized for their exceptional strength and flexibility. Their tapered design, featuring a smaller diameter at one end, helps distribute load evenly while reducing overall weight. This makes them ideal for high-stress applications, including sports equipment, drones, and aerospace parts.

Key Benefits of Carbon Fiber Tubes

- High Tensile Strength: Carbon fiber tubes can withstand extreme loads without deforming, making them superior to traditional materials like steel or aluminum.

- Corrosion Resistance: Carbon fiber is highly resistant to environmental wear, ideal for marine and outdoor applications.

- Thermal Stability: These tubes maintain performance under extreme temperatures, making them excellent for aerospace and industrial use.

Carbonoid Products: Advanced Carbon Fiber Tubes

At Carbonoid, we offer a wide range of carbon fiber products tailored to various industries. Here’s an overview of some of our top-selling products:

1. Pro-Taper Carbon Fiber Cue Shaft Blanks

- Applications: Billiard cues for professional play.

- Specifications:

- Length: 29-30 inches.

- Tip Diameter: Ranges from 11.5mm to 13mm.

- Finish: Matte, carbon, wood, or custom colors.

2. Conical Carbon Fiber Butt Tubes

- Applications: Custom cue butts for billiards.

- Specifications:

- Top Diameter: 21.4mm; Bottom Diameter: 31.5mm.

- Length: 29 inches.

- Finish: Available in natural carbon, blue, red, and more.

3. Custom Carbon Fiber Tubes

- Applications: Used across aerospace, marine, automotive, and sports industries.

- Specifications:

- Length: 500mm to 3000mm.

- Finish: Customizable with matte, 3K twill, and glossy options.

Technical Specifications of Carbon Fiber Tubes

Here’s a detailed table of key parameters for our carbon fiber tubes:

| Parameter | Description | Values | Applications |

|---|---|---|---|

| Material Type | Carbon Fiber (High-modulus/Standard-modulus) | High-modulus: 230-600 GPa | Aerospace, Structural Beams |

| Tensile Strength | Maximum stress when stretched | 2.5 – 3.5 GPa | Sports Equipment, Aerospace |

| Strength-to-Weight Ratio | Ratio of strength per unit density | 1500 kNm/kg | Lightweight Engineering, Drones |

| Flexural Strength | Ability to withstand bending | 1.6 – 2.0 GPa | Bicycle Frames, Automotive Parts |

| Corrosion Resistance | Resistance to environmental damage | High | Marine Engineering, Harsh Conditions |

| Thermal Resistance | High-temperature performance | 200-300°C | Aerospace, Industrial Machinery |

| Density | Material’s weight density | 1.5 – 1.6 g/cm³ | Lightweight Applications |

The Manufacturing Process at Carbonoid

We apply advanced manufacturing techniques to ensure each tube meets strict standards for quality and performance:

- Material Selection: We choose high-modulus fibers for stiffness or standard-modulus fibers for flexibility, depending on the application.

- Precision Layering & Wringing: Our experts use pre-preg carbon fiber (resin-impregnated) to wrap around a mandrel, forming the tapered tube.

- Curing Process: The tubes are cured in an autoclave, using heat and pressure to solidify the resin and eliminate air bubbles, ensuring top-quality material strength.

- Cutting & Finishing: CNC machines precisely cut the tubes to custom sizes. We offer various finishes, including matte or 3K glossy.

- Quality Control: Each tube is rigorously tested for taper accuracy, radial runout, and load-bearing capacity.

Why Choose Carbonoid?

- Customization: We specialize in tailored carbon fiber solutions for various industries, from aerospace to robotics. Whether it’s specific tapers, finishes, or dimensions, we deliver products that meet your exact needs.

- Advanced Manufacturing: With our cutting-edge facilities, including autoclave curing and CNC machining, we ensure precise, reliable performance in every tube we produce.

- High-Performance Materials: Our high-modulus carbon fibers offer the stiffness and strength required in demanding environments.

- Sustainability: Our processes are optimized to reduce material waste, and carbon fiber’s durability ensures long-term use, contributing to a more sustainable future.

- Global Reach: With clients in North America, Europe, and Asia, we offer efficient, reliable delivery across the world.

Industry Trends: The Future of Carbon Fiber

As the carbon fiber industry continues to evolve, these key trends are shaping the future:

- Demand for Lightweight Materials: Industries like aerospace and automotive are increasingly adopting carbon fiber to reduce weight while maintaining strength.

- Customization is Key: Clients now seek tailored solutions that fit specific needs, from unique dimensions to specialized finishes. Carbonoid provides fully customizable products.

- Sustainability: The focus on sustainability is driving innovations in material use, and carbon fiber is favored for its long-term durability and recyclability.

Common Applications of Carbon Fiber Tubes

- Sports Equipment:

- Used in billiard cues, fishing rods, and golf clubs, carbon fiber tubes provide exceptional strength without adding weight, improving overall performance.

- Aerospace & Drones:

- Tapered carbon fiber tubes are crucial in aerospace applications for their strength-to-weight ratio. They are often used in drone arms and aircraft components.

- Marine Engineering:

- Carbon fiber’s resistance to corrosion and UV rays makes it the go-to material for yacht parts and fishing rods.

- Robotics & Industrial Applications:

- Carbon fiber tubes reduce weight while maintaining strength, making them ideal for robotic arms and industrial automation systems.

Outbound Links

- For more details on tensile strength and material performance, check out this CompositesWorld article.

- Learn more about the advantages of carbon fiber on Wikipedia’s Carbon Fiber page.

At Carbonoid, we don’t just manufacture carbon fiber tubes—we partner with you to ensure the success of your project. Explore our carbon fiber tube specifications or reach out for a custom quote.