Custom-Made

Phenolic Resin CNC Parts for Aerospace & Energy

High-Performance Phenolic Resin Components – CNC Machined to Precision

Designed for insulation, durability, and thermal resistance in critical environments.

Flame-retardant, electrically insulating parts – Direct from the Manufacturer.

Why Choose Our Phenolic Resin Parts?

• Heat & Electrical Resistant:

Performs in high-temp and high-voltage conditions.

• Precision Machined:

±0.1mm tolerance supported for all custom shapes.

• Flame-Retardant:

UL94 V-0 certified for demanding aerospace use.

• Fast Lead Time:

Prototyping in 5–7 days, mass orders ship quickly.

• Low MOQ Support:

One-off custom parts and small batches welcome.

• Trusted by Engineers:

Used in aerospace, railway, and energy industries.

Phenolic Resin Tubes & Parts

Phenolic Resin Components We Offer

“Phenolic Resin Components Options” Describe the various products or categories, such as:

Phenolic Resin Tubes

Phenolic fabric tubes (also known as bakelite tubes or fabric-reinforced phenolic bushings) are manufactured by hot-rolling coarse or fine cotton fabric impregnated with phenolic resin.

These components offer excellent electrical insulation, high wear resistance, and outstanding mechanical strength.

They are ideal for custom-machined parts such as bushings, washers, and structural insulators.

Key features:

✅ Compatible with CNC machining, carving, and trimming

✅ Customizable diameters available through mold development

✅ Reliable performance in humid and oil-filled environments

✅ Flame-retardant and long-lasting for industrial applications

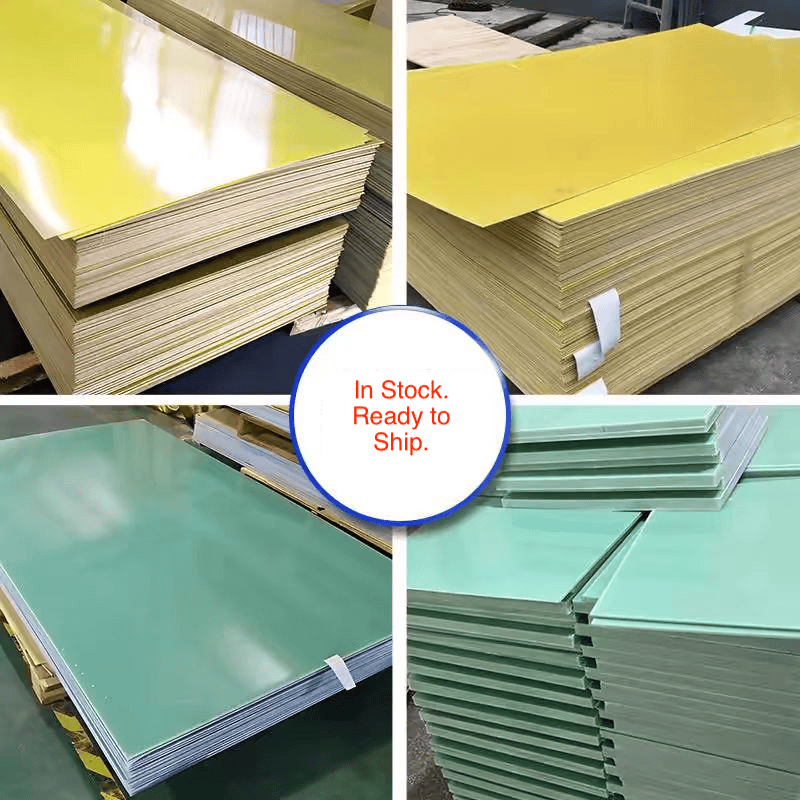

3240 Epoxy Resin Boards and Parts are made from fiberglass cloth impregnated with epoxy resin, then hot-pressed and cured. They offer excellent mechanical strength, dielectric performance, and heat resistance. Ideal for electrical insulation parts, especially in humid environments or transformer oil.

Highlights:

✅ Made from alkali-free fiberglass cloth impregnated with epoxy resin

✅ Excellent mechanical strength and dielectric performance

✅ Smooth surface with no bubbles, oil stains, or impurities

✅ Stable under high temperatures and transformer oil environments

✅ Available in a wide range of thicknesses and board sizes

✅ Supports CNC machining, drilling, trimming, and engraving

✅ Easy installation and long service life

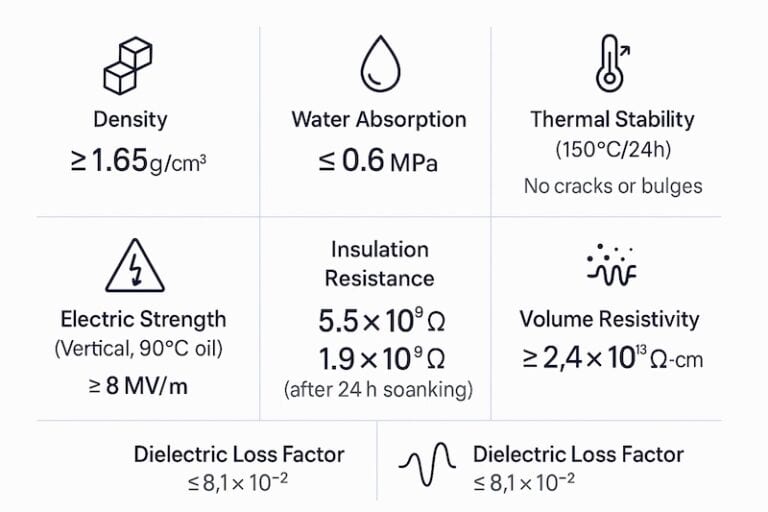

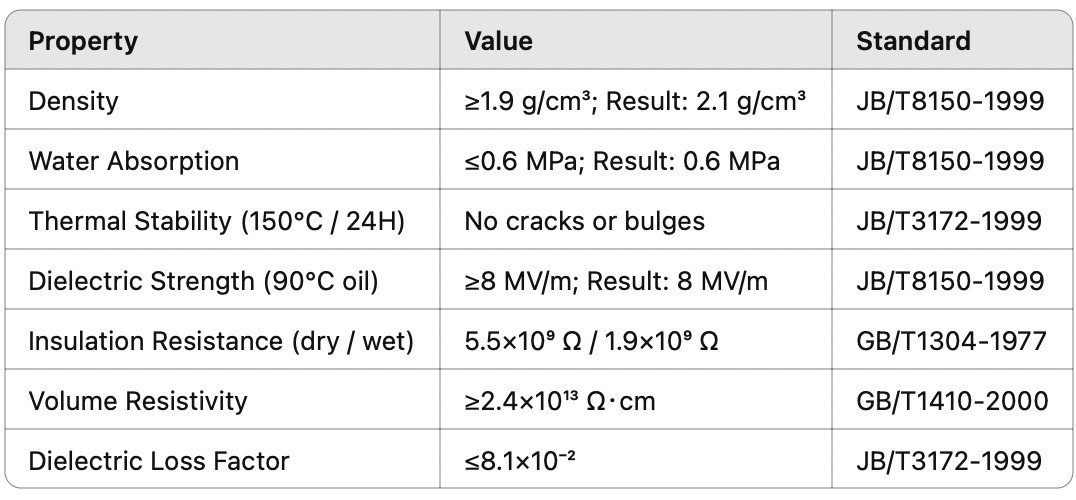

Technical Properties:

FR4 / G10 Epoxy Rods and Insulation Fasteners

Highlights:

✅ G10 / FR4 epoxy grade

✅ CNC machined into bolts, nuts, and fasteners

✅ Flame-retardant, acid- and oil-resistant

✅ Stable dielectric performance

✅ Smooth surface without air bubbles or contaminants

✅ Customizable diameters and lengths

✅ Long service life in harsh conditions

FR4 Epoxy Insulation Rods and Bolts are manufactured by pultruding fiberglass filaments impregnated with epoxy resin under high temperature and vacuum-controlled extrusion. These rods offer excellent dielectric properties, high mechanical strength, and smooth surfaces free from bubbles, oil, or impurities.

Available in multiple diameters (⌀6mm–⌀170mm), shapes (round, hex, square), and customizable lengths. Ideal for electrical insulation structures exposed to heat, humidity, and transformer oil.

FR-4 Fiberglass Epoxy Board – Custom Insulation Panels

Product Features:

Stable electrical insulation performance

Excellent flatness and smooth surface with no pits or dents

Flame-retardant, heat-resistant, and environmentally friendly

Sound-absorbing and thermal-insulating properties

Suitable for high-performance electrical and electronic insulation

Applications:

FR-4 fiberglass boards are widely used in:

FPC stiffeners and soldering-resistant carriers

PCB testing fixtures and precision gear plates

Electrical device insulation sheets and transformer parts

Motor insulation components and deflection coil terminal plates

Switch insulation boards and customized structural parts

Available Options:

Size: Customizable per request

Color: Standard water green

Thickness: Multiple options available

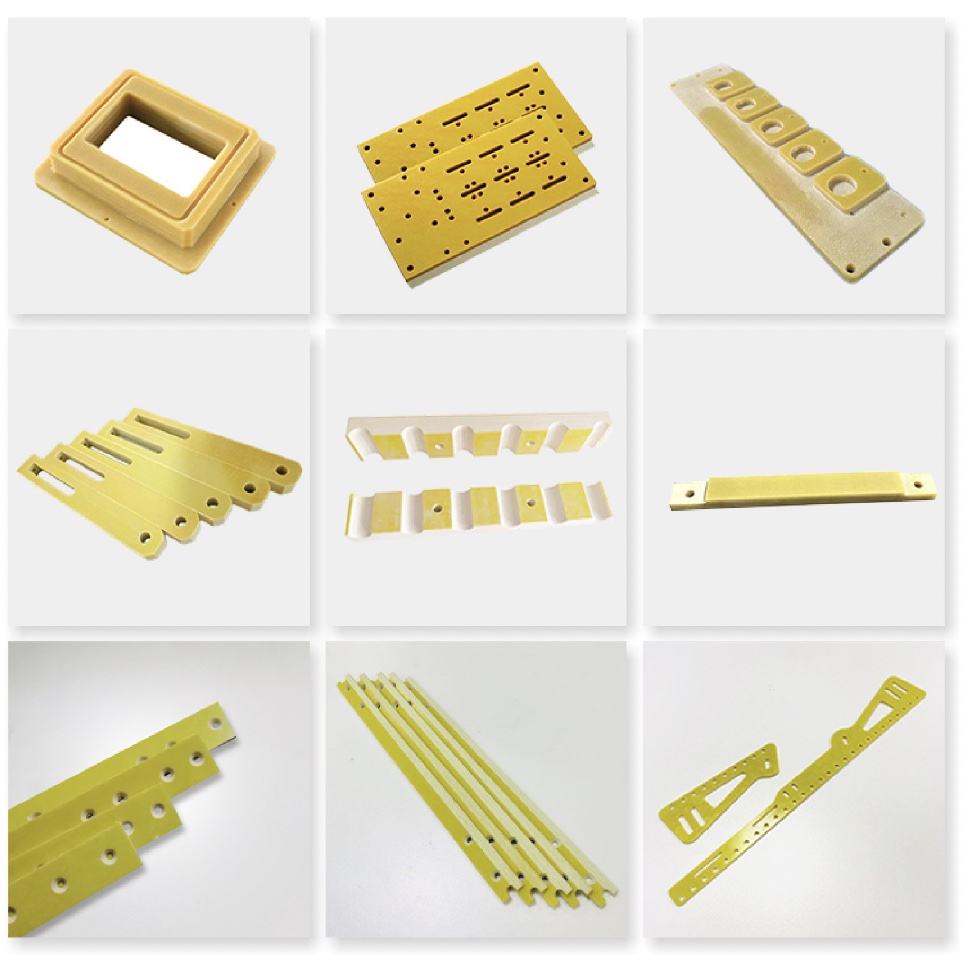

Real Samples — Machined from Phenolic Plates & Tubes

Phenolic Resin Machining Gallery

Quote in 24 Hours. Parts Ready to Ship in 7 Days.

Phenolic resin tube

Phenolic resin tube

Phenolic resin tube parts

Epoxy Resin Parts

Phenolic Resin Board

FR4 Glass Fiberglass board

FR4 Fiberglass board

Epoxy Resin Board

FR4 Glass Fiberglass Panel Green

Natural PPS Sheets & Rods – CNC Machined, GF40 Reinforced

Custom Phenolic Tube Sizes Available

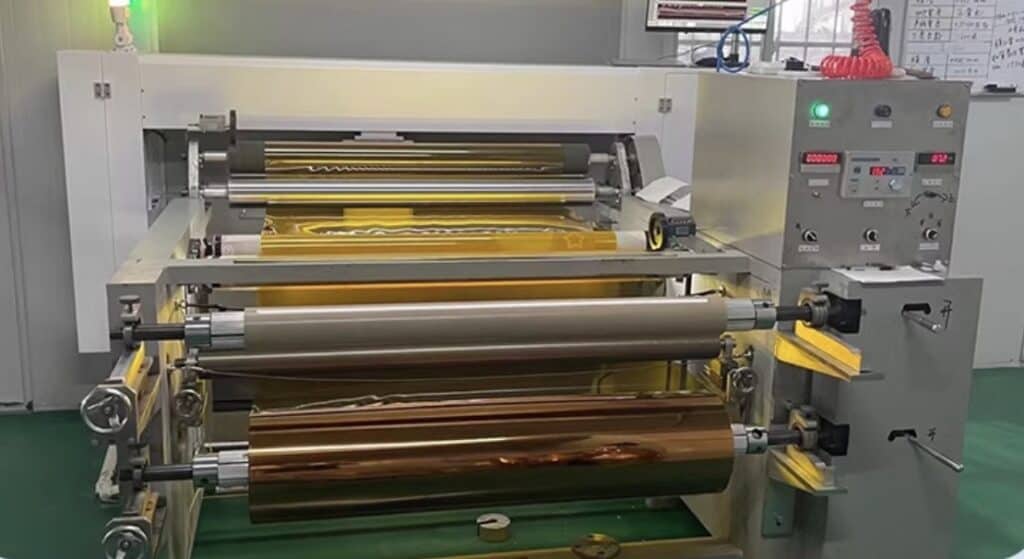

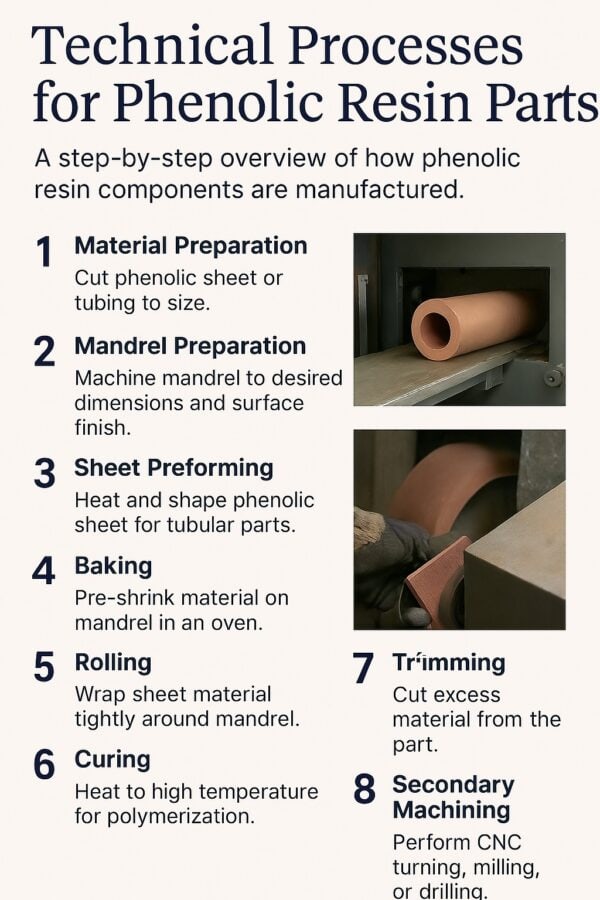

Some steps to produce

Phenolic Resin Part Manufacturing Process

A fast, traceable workflow for CNC-machined insulation components.

01

Material Selection

Select high-quality phenolic sheets or laminated tubes according to application.

02

Rough Cutting

Raw boards or rods are cut into manageable blanks for further processing.

03

Surface Planning

Ensure flatness or roundness before CNC machining for better accuracy.

04

CNC Programming

Import CAD drawings and set machining parameters based on tolerances.

05

Precision Machining

Use CNC routers or mills for drilling, slotting, contour shaping, and turning.

06

Chamfering & Deburring

Edge polishing and chamfering to avoid sharp edges or fiber burrs.

07

Dimensional Inspection

Check critical dimensions using calipers or 3D probes; tolerance ±0.1mm.

08

Surface Cleaning

Remove cutting dust and apply optional anti-humidity coating.

09

Packaging & Shipment

Parts are labeled, packed by batch, and dispatched within 7 days.

Custom Phenolic Resin Part Process

Quotes in 24 Hours. Prototypes in 7 Days.

Precision machining + fast delivery = efficient development for your engineering projects.

showing our commitment to speed, accuracy, and industrial-grade quality for phenolic insulation components.

A. Application Requirements:

Define working temperature, dielectric strength, or arc resistance based on use case (e.g., switchgear, aerospace, or rail systems).

B. Part Geometry:

Choose between plates, tubes, bushings, or blocks. Specify dimensions and wall thicknesses to match design.

C. Machining Type:

Drilling, slotting, surface routing, or full 3D CNC milling to meet part function and mounting needs.

D: Material Grade:

Select phenolic types like paper-based, fabric-based, or glass-filled based on insulation and strength needs.

E. Manufacturing Process:

All parts are machined from laminated phenolic stock. CNC processed with tight tolerances.

F. Surface Finish & Coating:

Edges chamfered or polished. Optional anti-moisture coating or sanding available.

G. Customization:

Add mounting holes, grooves, or notches based on drawing. Labeling and serial batch optional.

H. Quality Assurance:

Each batch checked for tolerance, flatness, and edge quality. Inspection report can be provided upon request.

Machining Service

Need Precision-Machined Phenolic Parts?