Introduce

Carbon fiber is typically chosen over traditional materials such as aluminum, steel, and titanium because of the following properties: High strength and stiffness to weight.

Carbon fiber tubes are used in numerous applications like tactical ladders, trusses, and beams.

Excellent fatigue resistance.

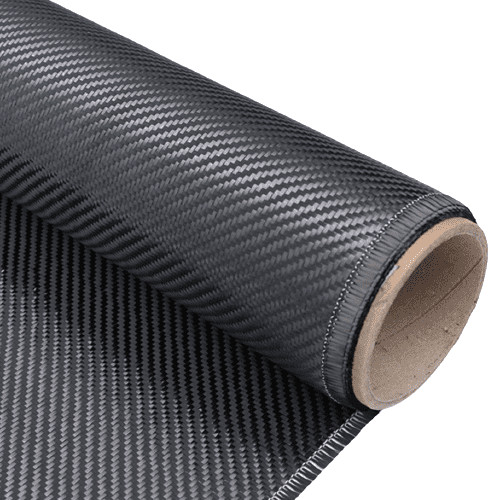

Carbon fiber raw material

The primary raw material is Carbon Fiber Fabric with Epoxy Resin or Fiberglass.

Carbon Fiber Fabric is made of carbon fiber by woven unidirectional, plain weaving, or twill weaving style. The carbon fibers we use contain high strength-to-weight and stiffness-to-weight ratios. Carbon fabrics are thermally and electrically conductive and exhibit excellent fatigue resistance. When properly engineered, carbon fabric composites can achieve the strength and stiffness of metals at significant weight savings. Carbon fabrics are compatible with various resin systems, including epoxy, polyester, and vinyl ester resins.

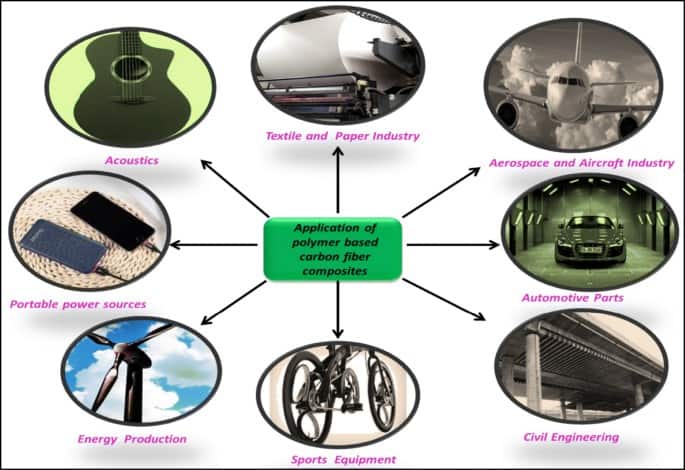

Characteristics and applications of carbon fiber

The Main Characteristics such as:

- High specific strength, high elasticity

- Fatigue resistance

- Thermal stability

- Conductivity

- Anti-vibration attenuation performance is superior

- Chemical stability

- Corrosion resistance

- Lightweight

- Non-toxic biological toxicity

The Main Applications such as:

- Aviation, aerospace, transportation, wind turbines, civil engineering, pumping rods

- Plate spring, helicopter rotor, the high-speed rotary body

- Electronic equipment, precision machining equipment, satellite equipment, instruments, weapons, and equipment

- Electrodes, composite core wire, the electromagnetic shield

- Machine arm, racket, fishing rod, golf pole

- C / C composite materials, high-pressure vessels, chemical equipment

- Chemical equipment, electrode materials, marine pipelines, oil tanks, building reinforcement materials

- Automotive, aerospace, sporting goods

- Medical supplies

Carbon fiber Prepreg weave

1K 3K 6K 12K or UD

Carbon Fiber Pipe Surface

The tubes weave:plain/twill/glossy/matte/UD

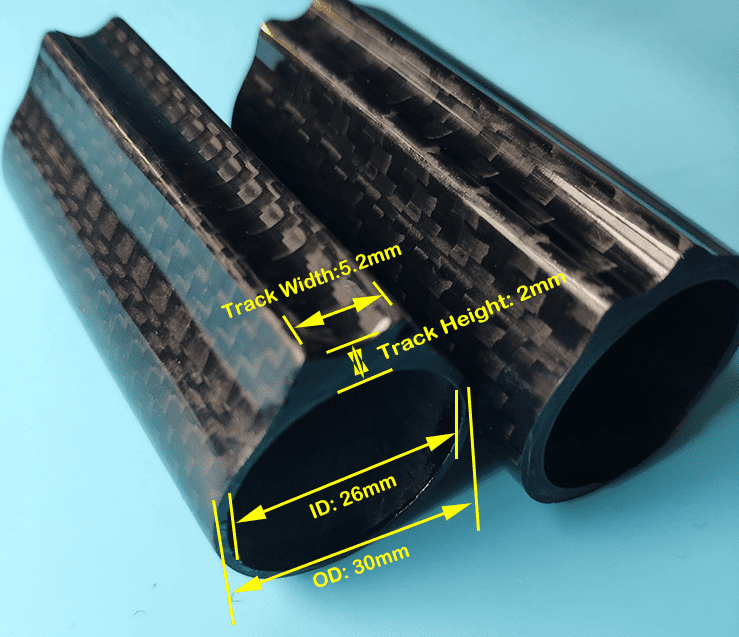

The Size

- Inner Diameter:from 3mm to 60mm

- Wall Thickness:0.5mm, 0.75mm, 1mm, 1.5mm, 2mm, 3mm, 4 mm

- Length:1000mm,1200mm,1500mm,2000mm

- Or custom wall thickness, length, or surface.

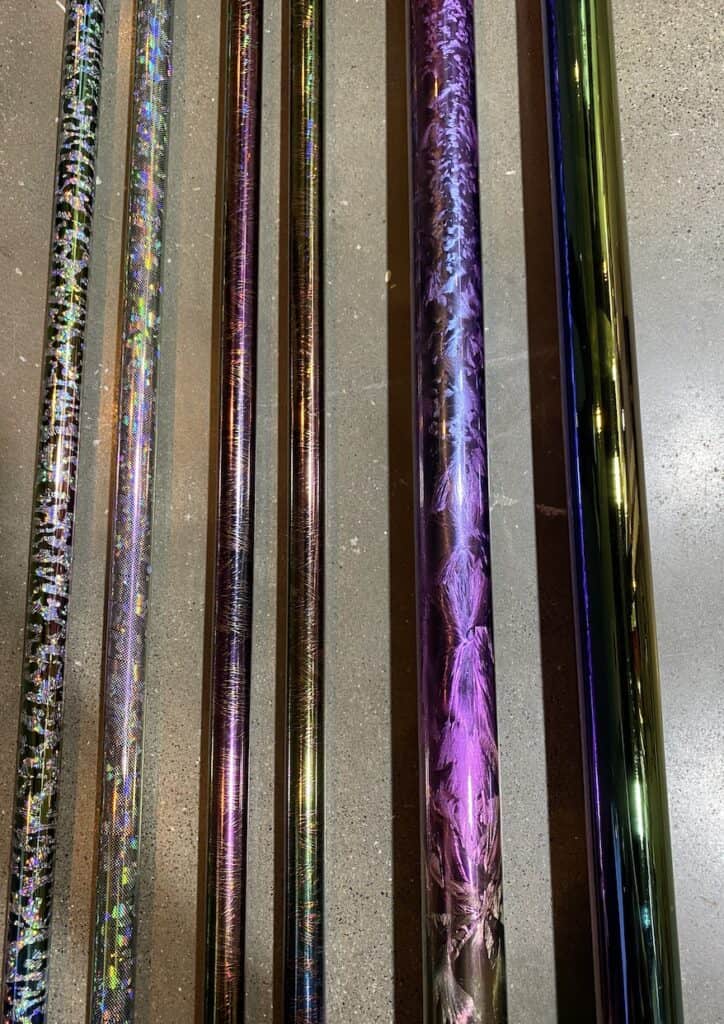

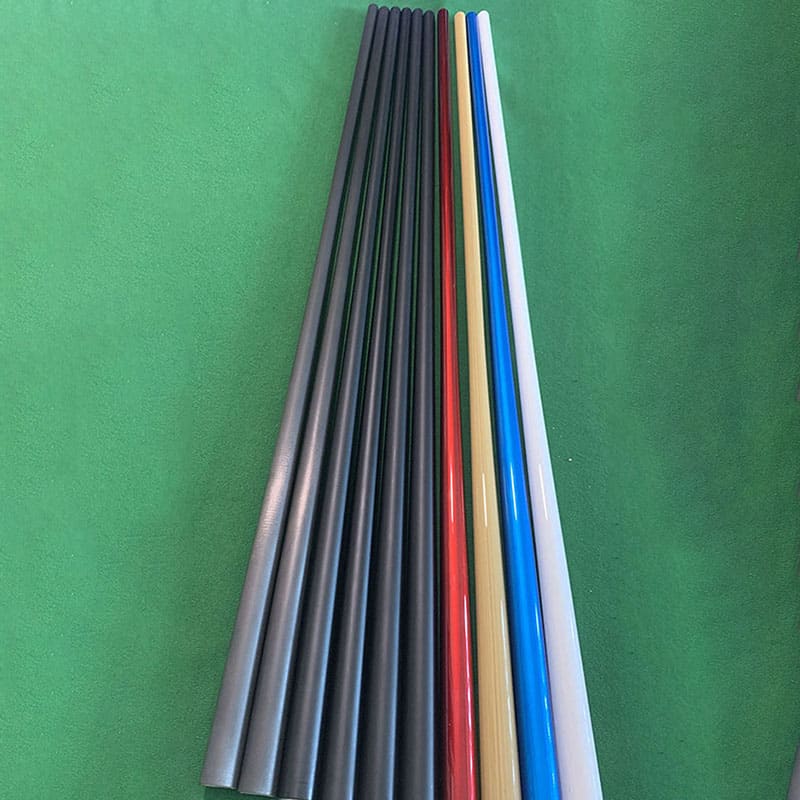

Carbon Fiber Pipe Colors

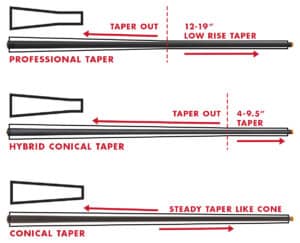

Carbon Tube Shape

Please advise if you need any other sizes of blank carbon fiber shafts Carbon Fiber Butt Tubes or Carbon Fiber Tubes; we will quote you the price and arrange samples for you.

Or Please go back to the Homepage to review more products and blogs. Thank you.

Don’t hesitate to contact us by email at daisyliu@carbonfibercue.com or on Facebook if you have any questions. Thank You!

- Why Square Carbon Fiber Tubes Are Essential for the Aerospace Industry?

Introduction: The Critical Role of Materials in Aerospace The aerospace industry is always looking for lightweight, durable, and high-performance materials to enhance the design and functionality of aircraft and spacecraft. One material that stands out in modern aerospace engineering is carbon fiber square tubes. Known for their strength-to-weight ratio, corrosion resistance, and design flexibility, carbon… Read more: Why Square Carbon Fiber Tubes Are Essential for the Aerospace Industry?

Introduction: The Critical Role of Materials in Aerospace The aerospace industry is always looking for lightweight, durable, and high-performance materials to enhance the design and functionality of aircraft and spacecraft. One material that stands out in modern aerospace engineering is carbon fiber square tubes. Known for their strength-to-weight ratio, corrosion resistance, and design flexibility, carbon… Read more: Why Square Carbon Fiber Tubes Are Essential for the Aerospace Industry? - The Comprehensive Guide to Pro-Taper Low-Deflection Carbon Fiber Shafts: Features, Insights, and Future Innovations

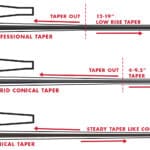

The Pro-Taper Low-Deflection Carbon Fiber Shaft represents a breakthrough in billiards technology, offering unmatched precision, durability, and control. Its advanced carbon fiber construction, low-deflection engineering, and premium Pro-Taper design make it a must-have for serious players. This blog explores its key features, such as ferrule-less technology, high-performance tips, and lightweight balance, while also diving into future innovations like nano-carbon materials, smart sensors, and self-healing technology. Whether you’re a professional or an enthusiast, this guide shows how Pro-Taper shafts can elevate your game to the next level.

The Pro-Taper Low-Deflection Carbon Fiber Shaft represents a breakthrough in billiards technology, offering unmatched precision, durability, and control. Its advanced carbon fiber construction, low-deflection engineering, and premium Pro-Taper design make it a must-have for serious players. This blog explores its key features, such as ferrule-less technology, high-performance tips, and lightweight balance, while also diving into future innovations like nano-carbon materials, smart sensors, and self-healing technology. Whether you’re a professional or an enthusiast, this guide shows how Pro-Taper shafts can elevate your game to the next level. - What’s the Best Pro-Taper Low-Deflection Carbon Fiber Cue Shaft (12.4mm)?

Finding the perfect Pro-Taper low-deflection carbon fiber cue shaft can be a game-changer for any billiards enthusiast. Whether you’re a professional or a casual player, choosing the correct shaft ensures precision, durability, and consistency. Let’s dive into the top 10 shafts and help you decide which one suits your needs best. Why Low-Deflection Shafts Matter… Read more: What’s the Best Pro-Taper Low-Deflection Carbon Fiber Cue Shaft (12.4mm)?

Finding the perfect Pro-Taper low-deflection carbon fiber cue shaft can be a game-changer for any billiards enthusiast. Whether you’re a professional or a casual player, choosing the correct shaft ensures precision, durability, and consistency. Let’s dive into the top 10 shafts and help you decide which one suits your needs best. Why Low-Deflection Shafts Matter… Read more: What’s the Best Pro-Taper Low-Deflection Carbon Fiber Cue Shaft (12.4mm)? - Why Are Carbon Fiber Tubes Leading the Future of Engineering?

Carbon fiber tubes are transforming industries due to their strength-to-weight ratio, corrosion resistance, and durability. At Carbonoid, we specialize in tapered carbon tube manufacturing, delivering innovative, lightweight solutions for applications in aerospace, sports, robotics, and more. What Are Carbon Fiber Tubes? Carbon fiber tubes are cylindrical components made from carbon fiber-reinforced polymer (CFRP), recognized for… Read more: Why Are Carbon Fiber Tubes Leading the Future of Engineering?

Carbon fiber tubes are transforming industries due to their strength-to-weight ratio, corrosion resistance, and durability. At Carbonoid, we specialize in tapered carbon tube manufacturing, delivering innovative, lightweight solutions for applications in aerospace, sports, robotics, and more. What Are Carbon Fiber Tubes? Carbon fiber tubes are cylindrical components made from carbon fiber-reinforced polymer (CFRP), recognized for… Read more: Why Are Carbon Fiber Tubes Leading the Future of Engineering? - How Is a Pool Cue Lathe Machine Tool Made?

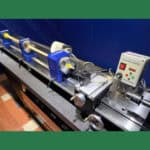

This article details the precise process of creating a pool cue lathe machine tool, covering stages like design, material selection, component manufacturing, assembly, and quality testing. By ensuring high accuracy and durability at every step, these machines are optimized to produce top-quality pool cues, meeting the demanding standards of professional cue makers and players. This guide provides insights into the advanced engineering and meticulous craftsmanship that make these tools essential for high-performance billiards equipment production.

This article details the precise process of creating a pool cue lathe machine tool, covering stages like design, material selection, component manufacturing, assembly, and quality testing. By ensuring high accuracy and durability at every step, these machines are optimized to produce top-quality pool cues, meeting the demanding standards of professional cue makers and players. This guide provides insights into the advanced engineering and meticulous craftsmanship that make these tools essential for high-performance billiards equipment production.